Inductive Charging

The abbreviation WiPT ['vai:pi:ti] denotes a certifiable standard for wireless power transfer. As the certification guarantees interoperability the abbreviation is deviated from "Wireless interoperable Power Transfer". The WiPT-standard aims to enable the installation of a public infrastructure of wireless power transfer to moving objects like vehicles or transportation containers. For that purpose a manufacturer independent and publically available description of the technology, especially the interface between the infrastructure and the vehicle is mandatory. Such an interoperability definition guarantees energy reception even under alternately operation of supply devices and vehicles which have been fabricated by various manufacturers.The devolopment of this standard has been funded by the Federal Ministry for the Environment, Nature Conservation, Building and Nuclear Safety through the joint research project "Inductive norm test by exchange in real operation (INTEROP)". The INTEROP-conclusion-report of this project can be downloaded in German language.

The Concept of Wireless Power Transfer

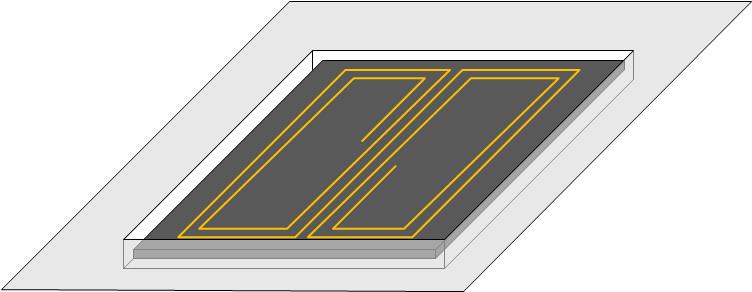

Using wireless power transfer shall simplify the process of charging the batteries of an electric vehicle, as the charging takes place completely automatically. Without connection of a plug the energy transfer starts simply by parking the car on a parking space. The use of wireless power transfer is already known from electrical tooth brushes which are also charged on a supply station without any metallic contactors. For that purpose the electric vehicle is equipped with a very thin consumer charging pad. The supply charging pad generates a magnetic field which is induced to the consumer pad that receives energy and charges the battery of the vehicle.

During the past years the concept of wireless power transfer has been technologically proven by many manufacturers as displayed at the right figure. Several vehicles approved for public traffic had already been equipped and operated many years. In order to maintain interoperability between vehicles of different manufacturers several competitors on the marked joint within the research project “InterOp” funded by the German ministry of environment to develop a interoperability definition. The WiPT-standard is based on these results.

Page Content

- Inductive Charging

Excamples of Applications

Currently about 10 vehicles equipped with inductive charging according to the WiPT-standard are in permanent use on public streets. Supply devices (“charging pads”) are delivered by two different companies whereas the vehicles are equipped by four different manufacturers. Some of the applications of the vehicles are shortly described within the following paragraphs.Vehicle Fleet of DB operated by InnoZ at the Berlin Euref-Campus

Very close to the Berlin Gasometer on the Euref-campus, used for famous television productions, the InnoZ operates a small fleet of three vehicles and three supply devices for the German railway company DB. Employees of the InnoZ use the vehicles for daily travels throughout the Berlin city region.

The charging pads are delivered by Vahle and SEW-Eurodrive, the on board charging technology of the vehiles are delivered by IPT, Vahle und SEW-Eurodrive. At this public available spot the advantage of interoperability can by daily experienced.

Domino's Pizza Delivery in Berlin Hellersdorf

At Domino's Pizza Service (previously Joey's) in Berlin Hellersdorf ordered food is delivered by an iMiEV which is inductively charged. At each stop in front of the shop the vehicle can be charged for a short time. This would not be done with conductive charging as the process of connecting is too much effort for the user and therefore is not be treated to be helpful. Nevertheless, as many such stops occur during the day, the sum of energy accumulated to a considerable amount. It has been proven the installed power of 3 kW is sufficient even for business use of the vehicles. The charging spot used at that spot is directly located beside a public street.

During the operation time since August 2015 already 1700 kWh of energy has been deliverd by the supply company E.On operating the charging pad.

Postal delivery with Streetscooter vehicles for the German Post

A vehicle side charging pad adopted for the Streetscooter transportation car has been developed by the EAI located in Ilsenburg. This development has been supported by the research institute ifak of Magdeburg. The car optimized for postal delivery can be constructed more user friendly by using the inductive charging system. The inductive charging also prepares the future use of autonomous driving. Just by reaching the loading ramp the vehicle can be charged. No precise plugging needing considerable technical effort is necessary with inductive charging as high positioning tolerances are acceptable.

Within the project "CO2-free delivery" further vehicles will be equipped with interoperable inductive charging in order to further simplify the usage for employees.

Company Vehicles of E.On/EDIS at the Airport Schoenefeld, Vahle in Kamen and the Berlin office of SEW-Eurodrive

At the Berlin Airport Schoenefeld E.On/EDIS operates an interoperable inductively charged vehicle for service purpose at the electric supply installations. At this site also 900 kWh energy has been supplied to the vehicle since August 2015.

Further company vehicles are used by Vahle und SEW at different site as displayed in above figures. Over all, four different vehicle types have been supported, applying different air gaps between the underbody of the vehicle and the street surface. All vehicle types are operating on the supply devices as all different vehicle component constructions are following the WiPT-standard.

Press publications

http://motordialog.de/md-messe-spezial-ecartec-induktion/ - Presentation at the eCarTec-fair 2016 in Munichhttp://ecomento.tv/2015/11/03/e-on-testet-induktives-laden-fuer-elektroautos-in-der-praxis/http://www.erneuerbar-mobil.de/projekte/interop

http://www.eon.com/de/presse/pressemitteilungen/pressemitteilungen/2015/10/21/eon-tests-inductive-charging-for-electric-vehicles-in-and-around-berlin-partners-are-edis-joeys-pizza-and-sew-eurodrive.html

http://www.streetscooter.org/forschung

http://www.german-e-cars.de/projekte/

https://www.innoz.de/de/interop-interoperables-induktives-laden

Technical parameters

Basically the WiPT-standard addresses the broadly spread application of inductive charging at public parking spots for example alongside the street, on parking sites of companies or shops but also at private spots. Within all those cases the user mainly uses the parking spot for parking his car, the charging of the car is just an additional service provided during that time. Such a spot might be called an “electric parking spot” designed for parking but also delivering power. (Never the less the WiPT-standard is desired not to be limited on such applications and is prepared to be extended to increased technical parameters and different mechanical constructions.)

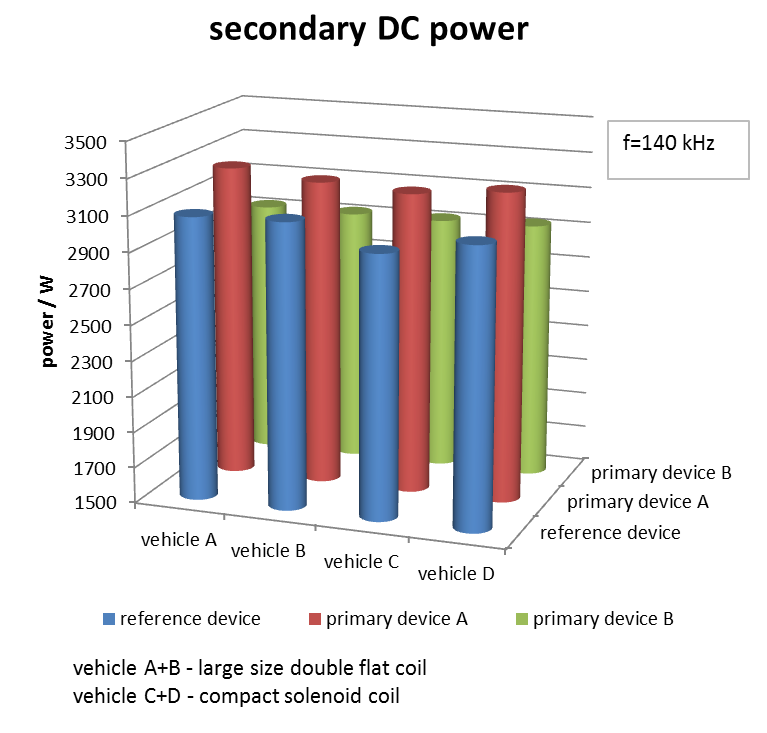

The broadly spread application in public areas requires the most difficult technical solution as the available supply power, the robustness, availability and service free operation needs to be solved as well as highest requirements for safety. These requirements have been fulfilled with the following technical parameters.- power: 3 kW

- operation frequency: 140 kHz

- active area of the ground pad 80 cm * 80 cm

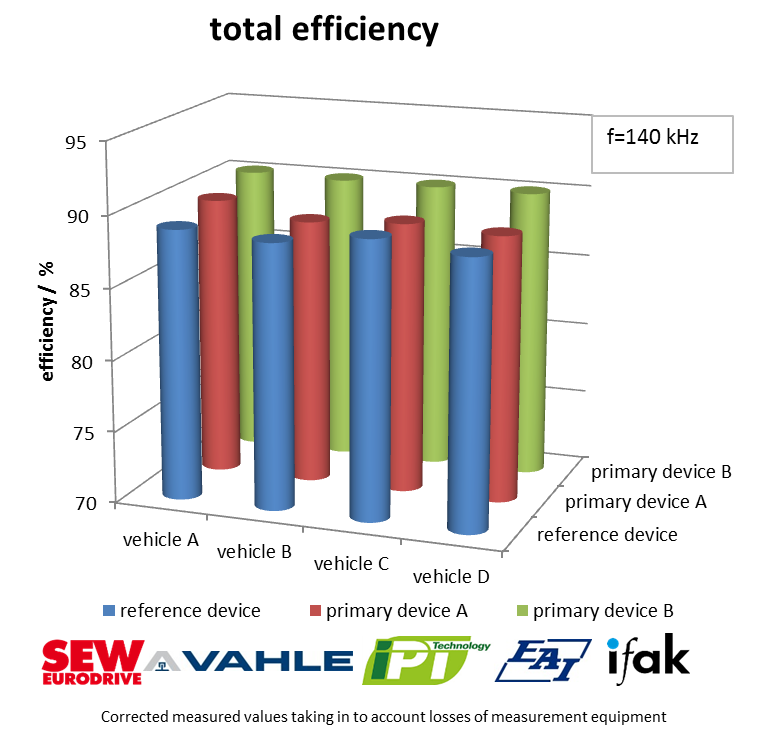

- efficiency: close to 90%

- horizontal positioning tolerance: +- 10 cm

To support the driver placing the car on the parking spot a display is installed to guide the driver to the best possible position.

Interoperability

Funded by the German Federal Ministry for the Environment, Nature Conservation, Building and Nuclear Safety four well known technology manufacturers joined within a research project. All companies having broad experience in wireless power transfer from industrial products and previous electro mobility research. Attended by scientific research institutes the aim has been to design a definition for interoperability.The resulting solution is based on a source definition. This definition concept is influenced by the conventional electric supply plug used in every house hold. Over the whole electric infrastructure of a country you can be sure to find the same kind of socket everywhere. Therefore, a distinct definition of the source site of the electric supply exists. On the other hand you can find all different kind of plugs, simple three connector plugs but also two connector plugs even having a charging device integrated. A distinct socket definition keeps flexibility for the plug design. To operate electrical devices it is also not important in which way the energy has been generated. It might have been generated by a power plant or by solar cells. Any load can be operated independent of the generation because only the interface parameters of the plug are relevant. Just the knowledge of the socket is important for interoperability. There are geometric parameters like the hole diameter and the contactor positions and electrical parameters like the source voltage that is supplied independent from the load conditions.

Following this concept for inductive charging a similar short and pregnant source definition has been defined, whereas the charging pad replaces the electrical socket. Only the supply pad is defined leaving flexibility to the design of the receiving pad. The geometric parameter of the hole size somehow correspondences to the magnetically conducting ferrite layer and the contactor positions to the winding position. The supply voltage as electrical source parameter correspondences to the current flowing within the windings (current linkage). Metaphorically spoken an “inductive socket” is provided.

International Standardization

It is one explicit goal of the Federal Ministry for the

Environment to provide scientific support to the standardization

process by funding the InterOp ("Inductive Norm Test by Exchange in

real Operation") project. Beside general requirements for inductive

charging the research was aimed to provide interoperability

requirements to the standardization. Setting up a public infrastructure

for wireless charging is not possible otherwise.Especially due to the pregnant interoperability definition the consortium of the technology manufacturers within the project succeeded in persuading the standardization working group to overtake the interoperability definition to the international standard.

In September 2015 this WiPT-interoperability definition has been described within the Annex AA as normative within the IEC 61980-3 standard suitable for inductive charging and has been published within the circle of experts.

Currently this Annex is the only manufacturer and technology independent standardization proposal providing an alternating operation of supply and receiver pads guaranteeing energy transfer. It is furthermore the only Annex that has proven functionality by daily operation of a larger vehicle fleet in public area (see “Examples of Applications”).

Inherent Safety

The WiPT-standard is designed in a way to allow the construction of inherently safe inductive power transmission. Inherently safe means a system is safe just by its construction and does not require additional active safety measures like detection systems for shut down of operation.Only such inherently safe systems can be expected to provide high availability, robustness and service free operation. Any sensing for safety would require regular test procedures to check functionality, thus increasing service needs and possible unavailability.

Inherent system safety is basically a question of the receiving pad design. If it is built as a large area device the resulting system is inherently safe and does not require sensing devices. Other manufacturers and customers prefer small receiving pads concentrating magnetic flux. In those (and just those) cases sensing and system shut down is required.

The following main aspects of safety especially related to the magnetic field have been investigated and solved.

Electrical Safety

In case of wireless power transfer no electric wire has to be

connected between the charge column and the vehicle. Beside the

increased comfort there is no risk for the user to handle a may be

damaged electric wire. Especially mechanical defects and aging of the

insulation might lead to an accident at wired charging which is not the

case for inductive charging increasing safety drastically. Also weather

conditions cannot lead to possible electric accidents as no metallic

parts are exposed to the surface.

Obstacle free Installation

The WiPT-standard

enables an on grade installation of the supply pad. Thus a flat and

obstacle free surface is reached. The possibility of a trip hazard is

avoided. Compared to charge columns a more elegant optic for the city

environment is reached especially at historic sites. No city furniture

disturbs traffic and pedestrians. An unused parking spot is kept free

for other usage. Absence of Magnetic Field during Disuse

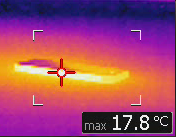

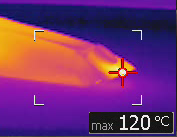

In case the supply pad is not used for charging it will not generate a magnetic field. This is necessary to avoid electrical losses reducing the efficiency. Furthermore during trespassing the pedestrian will not be exposed to a magnetic field. This behavior is reached because the vehicle needs to send a signal to the supply device in order to activate operation. This signal can only be received by the supply pad if the car covers the supply pad completely.Heating of Metallic Objects

During operation a magnetic field is applied between the

supply and the receiver pad. This field can penetrate magnetic objects

which might be located in between causing heat. Nevertheless objects of

daily use like coins, keys, beverage cans, tools and even mobile phones

have shown not to heat up significantly. Despite the relatively high

transmitted power from the supply to the vehicle this behavior is

possible because the area used for power transfer is quite large with

respect to foreign objects. Thus the power transferred within the

region of any foreign object keeps fairly low. Certainly, this behavior

is only possible, if a receiving pad also uses a large area for energy

transfer. This is not the case for any manufacturer as the

interoperability definition does not limit the design of the receiving

device. In case it is constructed using a small area, only, the

magnetic field concentrates below the receiving device, increasing the

flux density. This effect increases the heating effect to metallic

objects and might result in the need of metallic object sensing and

shutting down or at least limiting the energy transfer in such cases. |

|

|

|

|

|

A second measure used for wireless interoperable power transfer is the choice for a highest possible operating frequency of the alternating magnetic field. As described the flux density is most relevant for metallic object heating and should be kept as low as possible for inherent safety. From the physics it can be derived the inductively transmitted power is proportional to the flux density, the operation frequency and the used area. Thus the flux density reaches lowest possible values if most of the area below the vehicle and a high operation frequency is used. The limit is given by the radio frequency range which starts at 150 kHz. If the transmitted power is limited to small values (3 kW) as the available time for charging at parking is fairly long, the resulting flux density allows inherently safe operation.

Anti-Inflammatoy Design for Foreign Objects

Paper coated with a metallic skin as cigarette paper or tetra-packs carries the risk to inflame. The thin metallic surface might heat up to quite high values. As the heat capacity of this metal surface is very low no harm occurs by touching. Simply said, the finger will cool the metal more quickly as the metal heats up the finger. Nevertheless, the paper might be inflamed. Again (see “Heating of Metallic Objects”), this only happens at high flux density whereas at low flux density the paper might carbonize but is not inflamed. Therefore even for this possible risk under the given technical parameters an inherently safe solution has been reached.

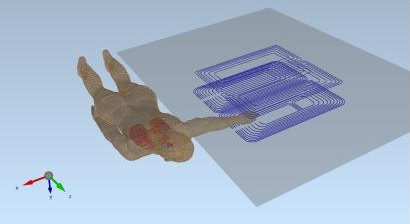

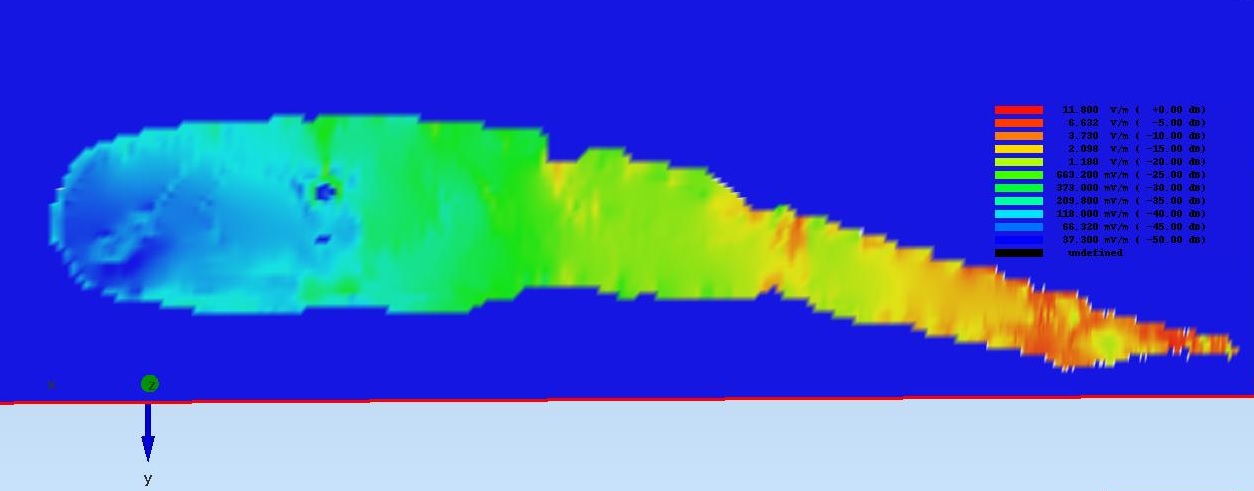

Effect of the Magnetic Field to the Human Body

Two effects are relevant for investigating the

influence of magnetic fields to the human body. At low frequencies

nerve stimulation is relevant, at very high frequencies the heating

effect is dominant. At the chosen operation frequency just below radio

frequency the nerve stimulation effect is already low whereas the

frequency is not high enough to cause heating. Limits valid for

permanent exposure are given by the ICNIRP-guideline. By body

simulations modelling the human tissues the relevant effects can be

calculated and compared to the basic limits. Such investigations have

been executed for the WiPT-standard

supply pad combined with an inherently safe receiver pad using a large

area for energy transfer and the mentioned operating frequency. The

given basic limits could be kept with such a design, even if a person

is lying beside the vehicle to grab something from the middle under the

car during operation.

To further benchmark the magnetic field strength a comparison to RFID (radio frequency identification tag) is quite interesting. RFID tags are e.g. used within super markets to identify certain products in order for theft protection or automatic payment. The inherently safe inductive charging pads are actually operating fairly close to the RFID operation frequency and even fulfill the electromagnetic compatibility emission limits. This coincidence also provides international acceptance for the frequency used for WiPT as RFID technology is accepted worldwide.

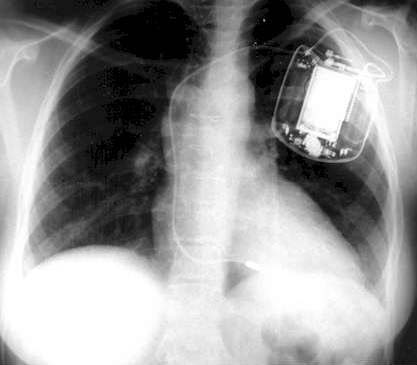

Safety for Persons Wearing Cardiac Pacemakers

Active body implants like cardiac pacemakers are usually

quite sensitive to external magnetic fields. Certainly, even pacemakers

must not be disturbed by operation of an inductive charging system.

Manufacturers of pacemakers guarantee unaffected operation below flux

densities of 6,25 µT at the desired operation frequency. The magnetic

field on the floor directly beside the car at positons the pacemaker

and its electrodes might be located is already much lower. Therefore,

even if someone wearing a pacemaker is grabbing something from

underneath the car is safe to do so.

To summarize all mentioned issues it is proved the WiPT-standard is able to provide inherently safe inductive charging. A precondition is a properly designed receiver pad using a large area for energy transmission. Therefore, concerning the widely spread inductive charging during parking, the technology does not necessarily require active sensors. Anyway, it would not be helpful for a user to find his vehicle uncharged in the morning because someone has thrown a coin under his car the last evening.

The inherent safe design delivers a robust design providing high availability and reliable operation for wireless and interoperable power transfer.